Nutrien’s growth ties closely to the success of Saskatchewan suppliers, key partners for decades

The story of Saskatchewan’s potash industry – much like potash itself – lies deep beneath the surface.

More than six decades ago, a team of innovative engineers and manufacturers found a way to move through underground water formations to access Saskatchewan’s rich potash ore bodies. Nutrien continues to draw on that spirit of innovation and teamwork, with more than 800 suppliers in the province playing a role in Nutrien’s long-term success.

“The potash industry is unique – and that leads to a lot of creativity in the mining companies and suppliers,” says Don Galbraith of Nutana Machine, which has designed and built conveyor systems used at Nutrien operations for more than 50 years. “From my perspective, that’s the most interesting part. A lot of innovation comes from within Saskatchewan. Without companies like Nutrien – with a lot of home-grown, quality people at the helm – companies couldn’t grow in a natural way.”

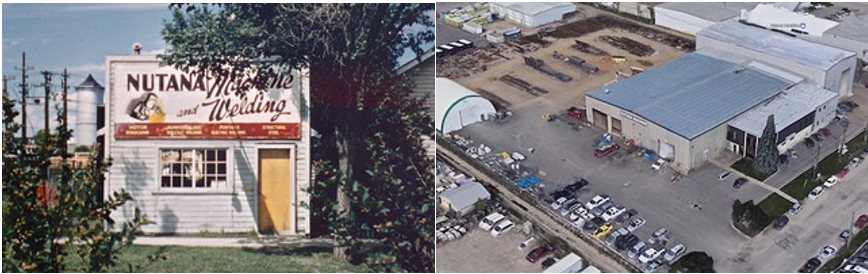

Nutana Machine: Original location (LH side) and it’s current industrial facility (RH side); showing the growth of the company/industry over the decades.

In 2023, Nutrien purchased about 75 percent of its potash goods and services – approximately $1.3 billion – from local suppliers. The company views that as an investment in industry partners who contribute to Nutrien’s pursuit of safer and more sustainable mining systems.

Nutana Machine: Intergenerational shot of Don and Todd Galbraith – second/third generation of the family involved with the company.

“We have a long history with many companies across the province and they’ve been key contributors to our growth over the decades,” says Trevor Berg, Senior Vice President, Potash Operations. “As we look to the future, we know that our success will be tied to the success of our Saskatchewan supply chain.”

The geology of potash deposits makes this industry different from hard-rock mining common in other parts of the world. That means Saskatchewan suppliers often need to produce homegrown solutions to uniquely Saskatchewan challenges.

For companies like KPCL Dirt Movers, based in Estevan, that involves understanding the nature of Saskatchewan soils to build better tailings management areas. KPCL was formed in 1953 and has decades of experience at potash operations across the province.

“We have the experience to know the stratigraphy of the soil and how the surficial dirt is different around the province,” says Riley Panteluk, Vice President of Operations for KPCL and grandson of company founder Kelly Panteluk. “Nutrien pursues early contractor engagement, so we can work with the company and engineering firms to design berms that use the soil in a way that is more effective.”

KPCL: Company founder, Walter Panteluk

As technology changes the global mining industry, many Saskatchewan companies are working on innovations tailored to the digital transformation of underground potash operations.

Dwayne Howatt of Continental Mine and Industrial Supply (CMI), which has designed customized solutions for the potash industry for over 30 years, believes there are breakthroughs on the horizon that will significantly increase the efficiency of underground operations – meaning capturing more of the valuable resource that is critical to the world’s future food supply.

CMI: Industrial Photos

“Saskatchewan has the best potash resources in the world and we need to use them properly,” says Howatt. “I see the (supplier) network as partners in Saskatchewan’s potash industry. A lot of us have built businesses to serve this industry. We’re part of one big team. If the industry struggles, we struggle. If the industry succeeds, we succeed. It works for all of us.”

Related stories