Celebrating Rail Safety Week with two of our warehouse supervisors

September 18-24, 2023 is Rail Safety Week in Canada and the US, and we’re grateful to our teams and leaders for always putting safety first.

At Nutrien, we can’t Feed the Future without safely moving products via rail.

That’s why rail safety is a top priority for our Transportation, Distribution and Logistics (TDL), Nitrogen, Phosphate, Potash and Retail groups, as well as the teams at our 20 Distribution Terminals across North America.

“This year, September 18 marks the start of Rail Safety Week in Canada and the US,” says Elan Strueby, Vice President, TDL. “This is a great opportunity to remind everyone to keep safety top of mind, whether you work directly with rail cars or are out near a railway in the community. I’m proud of our teams for upholding Nutrien’s core value of safety every day, and I’m grateful for the work they do to safely transport our products.”

To help celebrate Rail Safety Week, two of our warehouse supervisors share their experiences and advice when it comes to rail safety – and we have some fun facts about Nutrien’s rail fleet, shipments and new technology that you don’t want to miss.

Russell Tucker, Fort Dodge Warehouse Supervisor

At 21 years old, Russell started working at Nutrien as an Equipment Operator. In 2001, he became the Warehouse Supervisor at our dry storage terminal in Fort Dodge, Iowa, and has been in that role for the past 22 years.

“My favorite part of the job is the satisfaction of helping to provide fertilizer to farmers so they can grow crops,” he says. “Rail is such a big part of the supply chain – without railroads, there wouldn’t be enough vehicles to handle transporting our products – and that’s why rail safety is so important.”

Under Russell’s supervision, the team members at Fort Dodge are empowered to use their stop work authority in the event of a potential safety issue.

“We perform a job briefing before going out to bring rail cars in to unload them. There’s always a plan in place and we talk about how many cars we’re going to pull and where they’re going,” explains Russell. “The big thing in terms of safety is communication. If communication is ever lost between the locomotive operator and engineer, for example, our people know to use their stop work authority to regain communication before continuing their work.”

The team also ensures that every time they go out to pull rail cars, they perform a safety check by walking along and examining the cars and wheels to ensure nothing is broken.

“Last month, the team unloaded 22,000 tons of product. They do an exceptional job, always maintain strong communication and trust each other,” says Russell. “Trust and communication are key, and I truly appreciate everything the team does.”

Kevin James, Hammond Warehouse Supervisor

Just three months ago, Kevin joined Nutrien as the Warehouse Supervisor at our dry storage facility in Hammond, Indiana. While he’s new to the organization, Kevin brings a wealth of knowledge from working in rail for the past 12 years.

When it comes to safety, Kevin and Russell are on the same page – communication is key, and everyone maintains the authority to stop work to mitigate potential safety issues.

“It’s important that the team always looks out for each other, and we abide by the standard of The Nutrien Way to stop work to create a safe environment that ensures everyone knows what’s going on,” says Kevin. “For example, if we lose connection between our communication devices, we stop work and check in to help our conductors and engineers get back on the same page.”

Kevin and the team at Hammond work hard to maintain a safe facility, but even when rail cars aren’t tied to an engine, people still need to be careful around them.

“Rail cars are big pieces of machinery – they weigh a lot and have the potential to cause injuries,” Kevin says. “That’s why everyone needs to be very situationally aware when working around them. I would encourage everyone to remain vigilant and be aware of your surroundings when you’re near rail cars. This safety mindset is so important and helps everyone go home safe, every day.”

Fun Facts: Nutrien rail edition

- Nutrien utilizes 17,000 unique rail cars as part of its rail fleet.

- In 2022, Nutrien shipped 12,768,614 ST, which equals the weight of approximately 43 Mount Rushmore(s).

- If 1 shipment = 1 person, Nutrien made 75,959 shipments last year, which is enough to fill the Sydney Opera House 13 times.

- Nutrien is developing technology to robotically open and close rail car lids. Once operational, it will have the potential to improve loadout efficiency while reducing worker exposure to potential hazards.

Nutrien’s North American Distribution Terminals

Related stories

Explore more about Nutrien

Sudeepta Mohapatra loves the thrill of the chase

In my role I track the global agricultural fundamentals that help in predicting short to long-term trends driving the future direction of the global agriculture industry. I also develop and update various economic models. These models are used to estimate and predict crop input expenditure in our [...]

Read more

Nutrien Releases 2023 Global Community Impact Report

Nutrien’s Community Relations & Investment (CRI) supports our business purpose by nurturing communities through collaborations with community partners who share our values and help us to make a positive and lasting impact in the communities where we operate. “While we share CRI data and stories [...]

Read more

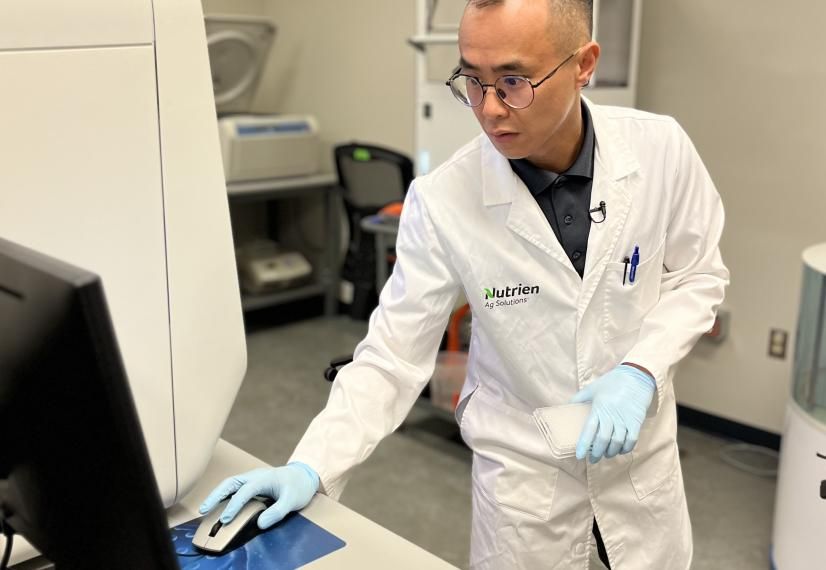

Using DNA analysis to make more resilient crops

Did you know that Nutrien has a Genotyping lab? It’s located in our Canola breeding facility in Saskatoon, Saskatchewan. Employees like Li Tan, Lead, Molecular Biology, work in the lab to analyze DNA for specific genes within plants.

Read more